GST : 24AADCR2517B1Z0

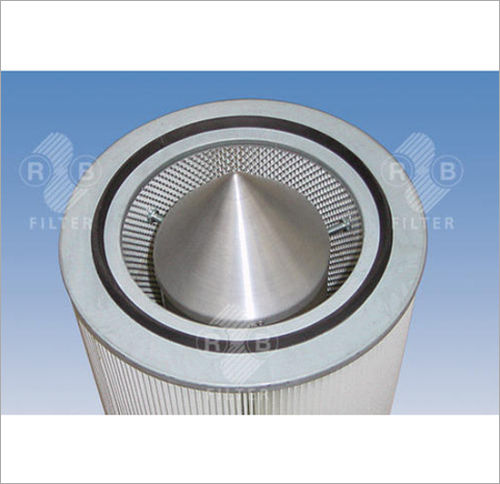

Filter Cartridge Venturi Nozzles

400.0 INR/Unit

Product Details:

- Product Type Filter Cartridge

- Usage Industrial

- Color Sliver

- Size Standard

- Filter Media Polypropylene (PP)

- Material Stainless Steel

- Warranty 1 Year

- Click to view more

X

Filter Cartridge Venturi Nozzles Price And Quantity

- 5 Unit

- 400.0 INR/Unit

Filter Cartridge Venturi Nozzles Product Specifications

- Industrial

- Filter Cartridge

- Sliver

- Standard

- Polypropylene (PP)

- Stainless Steel

- 1 Year

Filter Cartridge Venturi Nozzles Trade Information

- Mundra

- Cash Advance (CA)

- 1000 Unit Per Year

- 3 Week

- No

- Contact us for information regarding our sample policy

- All India

Product Description

Our Filter Cartridge Venturi Nozzle is a dependable and essential part of any filtration system since it was engineered with precision and made with high-quality materials. Its clever construction uses the Venturi effect to provide a strong suction that considerably enhances the filtering process. Say goodbye to clogged filters and subpar filtering outcomes with the help of this product. It successfully removes dirt, silt, and pollutants from the filter cartridges to guarantee a steady stream of clean, purified water or air.

Filter Cartridge Venturi Nozzle Applications:

- Chemical Processing: Filter cartridge venturi nozzles are utilized in chemical processing industries for filtration and separation of various chemical compounds, suspensions, and solutions. They help in maintaining product quality, removing impurities, and ensuring process efficiency in chemical manufacturing processes.

- Oil and Gas Industry: In oil refineries, petrochemical plants, and natural gas processing facilities, these nozzles are used for filtration and separation of hydrocarbons, contaminants, and particulate matter from crude oil, refined products, and gas streams. They aid in the purification of fuels, lubricants, and other petroleum products, ensuring compliance with industry standards and regulations.

- Food and Beverage Processing: Filter cartridge venturi nozzles find applications in the food and beverage industry for filtering liquids such as juices, syrups, dairy products, and alcoholic beverages. They help in removing impurities, bacteria, and particles from process fluids, ensuring product quality, safety, and compliance with food safety regulations.

- Pharmaceutical Manufacturing: In pharmaceutical production facilities, these nozzles are used for filtration and clarification of pharmaceutical solutions, suspensions, and intermediates. They help in removing microbial contaminants, particulates, and impurities from drug formulations, ensuring product purity, efficacy, and compliance with regulatory requirements.

- Industrial Air Filtration: Filter cartridge venturi nozzles are employed in industrial air filtration systems for removing dust, pollutants, and airborne particles from indoor air environments. They help in maintaining air quality, reducing airborne contaminants, and protecting workers health and safety in manufacturing facilities, warehouses, and commercial buildings.

Filter Cartridge Venturi Nozzles FAQ:

Q: How does a filter cartridge venturi nozzle work?

A: Filter cartridge venturi nozzles work based on the principle of the venturi effect, which states that when fluid flows through a constricted section of a pipe, the velocity of the fluid increases while the pressure decreases. This decrease in pressure creates suction, which helps draw fluid through the filtration media, enhancing filtration efficiency.

Q: What are the advantages of using filter cartridge venturi nozzles?

A: Some advantages of using filter cartridge venturi nozzles include:

- Improved filtration efficiency

- Enhanced fluid flow rates

- Reduced maintenance requirements

- Increased system performance

- Compatibility with various filtration media and systems

Q: Where are filter cartridge venturi nozzles commonly used?

A: Filter cartridge venturi nozzles find applications in various industries and processes, including:

- Water treatment plants

- Wastewater treatment facilities

- Chemical processing industries

- Oil and gas refineries

- Food and beverage processing

- Pharmaceutical manufacturing

- Industrial air filtration systems

Q: Can filter cartridge venturi nozzles be customized for specific applications?

A: Yes, filter cartridge venturi nozzles can be customized to meet the specific requirements of different filtration applications. They can be designed with various materials, sizes, shapes, and configurations to optimize performance and compatibility with different filtration systems and media.

Q: How do I select the right filter cartridge venturi nozzle for my application?

A: Selecting the right filter cartridge venturi nozzle involves considering factors such as:

- Flow rate and pressure requirements

- Filtration media and particle size specifications

- Compatibility with existing filtration systems

- Chemical compatibility with the fluid being filtered

- Operating conditions (temperature, pressure, etc.)

- Consulting with filtration experts or suppliers can help in selecting the most suitable venturi nozzle for your application.

Robust Construction for Industrial Use

Built with stainless steel, our Venturi nozzles provide superior resistance to corrosion and wear, making them suitable for continuous industrial operation. The use of premium materials enhances the lifespan of the product, ensuring it withstands demanding work environments while maintaining high performance.

Efficient Filtration with Polypropylene Media

These nozzles use polypropylene (PP) filter media, offering excellent chemical resistance and fine filtration capabilities. The combination of stainless steel body and PP media provides a reliable solution for capturing impurities, extending filter life, and lowering maintenance frequency in industrial systems.

FAQs of Filter Cartridge Venturi Nozzles:

Q: How are Filter Cartridge Venturi Nozzles used in industrial applications?

A: Filter Cartridge Venturi Nozzles are integrated into filtration systems to enhance the removal of fine particulates and contaminants from various industrial fluids. Their design optimizes flow and increases filtration efficiency, making them vital in sectors such as chemical processing, manufacturing, and water treatment.Q: What materials are used in these Venturi nozzles, and why is that important?

A: These nozzles are constructed from high-quality stainless steel and utilize polypropylene (PP) as the filter media. Stainless steel provides long-term durability and corrosion resistance, while PP ensures effective filtration and compatibility with a wide range of industrial chemicals.Q: When should I replace the filter cartridge in the Venturi nozzle?

A: Cartridge replacement depends on usage intensity and the level of contaminants in your system. Typically, it is advisable to monitor pressure drop or changes in filtration efficiency, and replace the filter cartridge when a decline in performance is observed or as recommended by your maintenance schedule.Q: Where can I install these Filter Cartridge Venturi Nozzles?

A: These nozzles are suitable for installation in industrial filtration units, process vessels, pipelines, and water treatment systems. They are especially effective in environments requiring robust construction and efficient contaminant removal.Q: What is the process for ordering these nozzles if I am an international client?

A: As an exporter, manufacturer, and supplier based in India, we streamline international orders by coordinating closely with clients to meet specific requirements, ensure proper documentation, and arrange secure shipping to your location worldwide.Q: What are the benefits of using stainless steel Filter Cartridge Venturi Nozzles with polypropylene media?

A: The combination provides outstanding durability, chemical resistance, and efficient filtration. This minimizes downtime, reduces maintenance requirements, and protects your systems from premature wear due to contaminants, translating to long-term cost savings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free